HAVE IT YOUR WAY

Prime Energy Resources Development B.V.(Previously Shell Philippines Exploration B.V. SPEX)

Malampaya, Puerto Princesa, Palawan

- Assist ROV Specialist to access overboard concrete gravity structure(CGS) through rope access for the inspection of subsea piping.

- Inspection of piping structure of Turbine Generator's Chimney.

- Dismantling and replacing Boom Crane's railway and platform utilizing rope access

Kone Elevator

Makati City

- We assist the Preventive Maintenance crew to reposition the elevator counterweight wire cable during the shutdown operation of Citi Bank Plaza Building at Bonifacio Global City, Taguig City.

Orica Philippines Incorporated

Subic Bay Morong, Bataan

- Magnetic Particle Inspection of welds on 36 tons capacity Container Van Spreader Beam.

Republic Cement

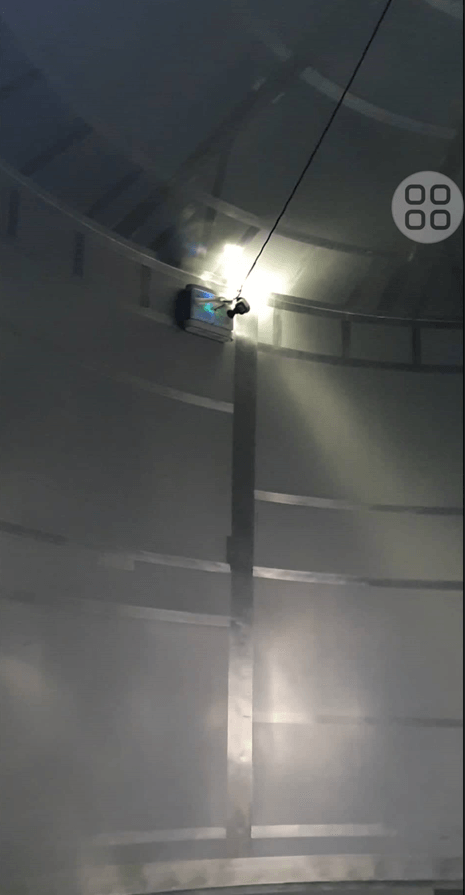

- Perform an internal visual inspection of the silo.

- Silo inspection is the most effective preventive method to ensure concrete and steel structures, surfaces, and silos. Regular maintenance and silo inspection increase your concrete's life and ensure the continued safety of those working around your structures.

- BIISCORP successfully conducted Non-Destructive Testing (NDT) inspection services on the Vertical Raw Mill unit utilizing IRATA-certified rope access technicians. This method allowed for safe and efficient access to elevated and confined components without the need for scaffolding or heavy equipment, minimizing plant downtime and associated costs.

The scope of inspection included:

Shell and liner welds—examined via Magnetic Particle Testing (MT) for surface-breaking discontinuities.

Support rollers, table segments, and separator housing—subjected to Ultrasonic Testing (UT) and Visual Testing (VT) to assess thickness loss, wear, and internal flaws.

Welded connections and structural attachments—inspected with MT and VT to verify integrity and compliance with relevant standards.

All inspections were performed in accordance with international standards such as ASNT SNT-TC-1A and API RP 571. Detailed reports with photographic documentation, weld maps, and evaluation results were submitted to the client for maintenance planning and recordkeeping.

Other Clients

- Frontken Philippines Inc.

- Reliability and Integrity Management Philippines Inc.

- Asia Corrosion Services Inc.

- Triple A Maintenance and Manpower Resources Contract Employment Services

- JAMES HARDIE Philippines

- GEF Industrial Supply and Services

- Powerflow Industries Inc.

- Siegen Philippines Inc.

- Alaska Milling Corporation

- Republic Cement

- MNJLM

- GHD Australia PTY LTD.

- BENLINE AGENCIES - Marine Agency Services and Integrated Logistics

- Puerto Primera Inc.

- ARTIFEX Master Builders

- BSTech Engineering Construction Corporation (Uni Oil Petroleum Philippines Inc. project)

- Hi-Grits

- HM Cryogenics

- NFF INTERNATIONAL

- GNPOWER KAUSWAGAN

- ASSTRA UK Logistics

- INVERT ROBOTIC